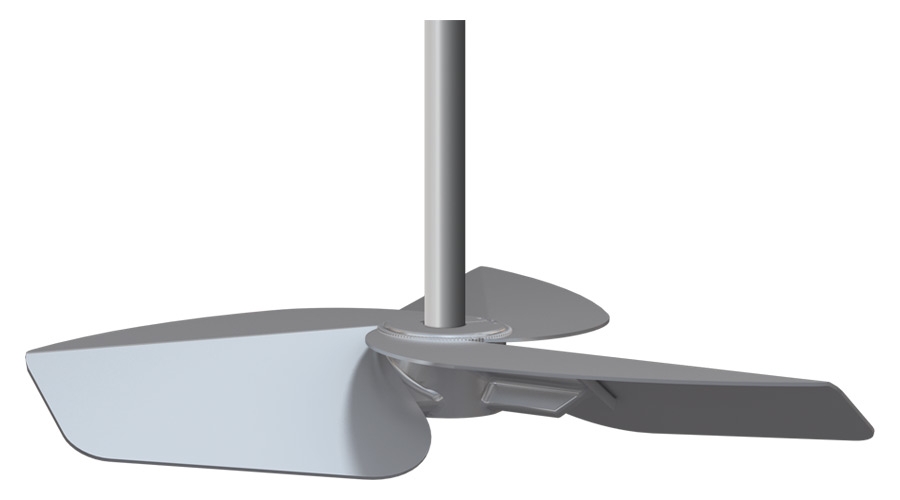

RL-3

Comparison of the Performance of the New RL-3 Impeller to the HE-3 Impeller in a Water Treatment Application

Plant Information:

Pinellas County Florida, South Cross Bayou WRF

Application Information:

Anoxic Basin: Start-up in 2000

Basin Dimensions: 40' long by 35' wide by 17' water depth

Plant Flow: 21 MGD average

Agitators Compared:

5hp at 30 rpm unit with 94" diameter HE-3 up-pumping impeller

5hp at 30 rpm unit with 84" diameter RL-3 down-pumping impeller

| HE-3/RL-3 Initial Installation | HE-3/RL-3 After 8 Weeks Operation | |

|---|---|---|

| HE-3 |  |  |

| RL-3 |  |  |

SUMMARY

Maintenance Benefits

- Customer had to drain the basin and increase flow rate to other basins which required manual changes to the process

- Outfitting personnel for basin entry and removal of fibrous material is eliminated

- Disposal issues of fibrous material eliminated

Mechanical Benefits

- Increased up-time of your plant

- Reduces load on agitator system such as gears, bearings, motor, shaft, and impeller blades

- Reduced vibration and increased life of agitator

Process Benefits

- Increased process up-time and elimination of manual process changes

- Elimination of fibrous material on impeller maintains top to bottom flow pattern which improves solids suspension and blending uniformity in basin

- Reliable and consistent discharge within plant operating permit limits